Group of Permanent Magnets and Applications

-

The team

The Group of Permanent Magnets and Applications is integrated in the Program Nanoscience for Critical Raw Materials of IMDEA Nanoscience and is constituted at present by:

Dr. Ester M. Palmero - Postdoctoral researcher

Dr. Cristina Navío - Postdoctoral researcher

Dr. Andrés Martín Cid - Postdoctoral researcher

Dr. José Luis Fernández Cuñado - Postdoctoral researcher

Dr. Cyrus Zamani - Postdoctoral researcher

Dr. Hari Krishnan - Postdoctoral researcher

Dr. Anas Eldosouky - Postdoctoral Researcher

Jimena Soler - PhD student

Alonso J. Campos - PhD student

Adrián Fernández - PhD student

Zaida Curbelo - PhD student

Carlos Iglesias - PhD student

Cristina Montero - PhD student

Jorge Vergara - PhD student

Iban Llamas - PhD student

Claire Frank - Master student

Jorge López - Research Assistant

Javier de Vicente - Technician (3D printing and automatism solutions)

The Program Nanoscience for Critical Raw Materials is working closely with the Program Nanomagnetism (coordinated by Prof. Julio Camarero) at IMDEA Nanoscience.Group of Permanent Magnets and Applications at IMDEA Nanoscience.

The Group of Permanent Magnets and Applications is working on fundamental and applied aspects of permanent magnets with no or reduced content of critical raw elements (rare-earths). The scope is the complete or partial substitution of strategically and costly rare earths (Nd and Dy) in technological permanent magnets in close collaboration with EU industrial partners. The main research lines are:

◦ Systems under study: MnAl-based, MnBi, L10-FeNi, ferrites, hybrid ferrite/NdFeB systems;

◦ Development of nanocrystalline permanent magnets without critical raw materials (rare-earths);

◦ Preparation and characterization of model magnetic nanostructures: thin films and multilayers;

◦ Nanoparticle engineering to synthesize nanoparticles with complex structures and tuned properties;

◦ Electrochemical synthesis of nanowires with permanent magnet properties;

◦ Advanced 3D-printing technologies of magnetic and metallic materials;

◦ Improved and novel technological applications of permanent magnets and magnetic sensors;

◦ Recovery and recycling of permanent magnets in industrial plants.

The quality of the research carried out by the team is proven by 15 initiatives (national and international ones) coordinated or with a P.I. role by the team during the last 5 years. Detailed information about the projects can be found in the Section Projects of this website.

Scientific and technological initiatives coordinated by the Group:

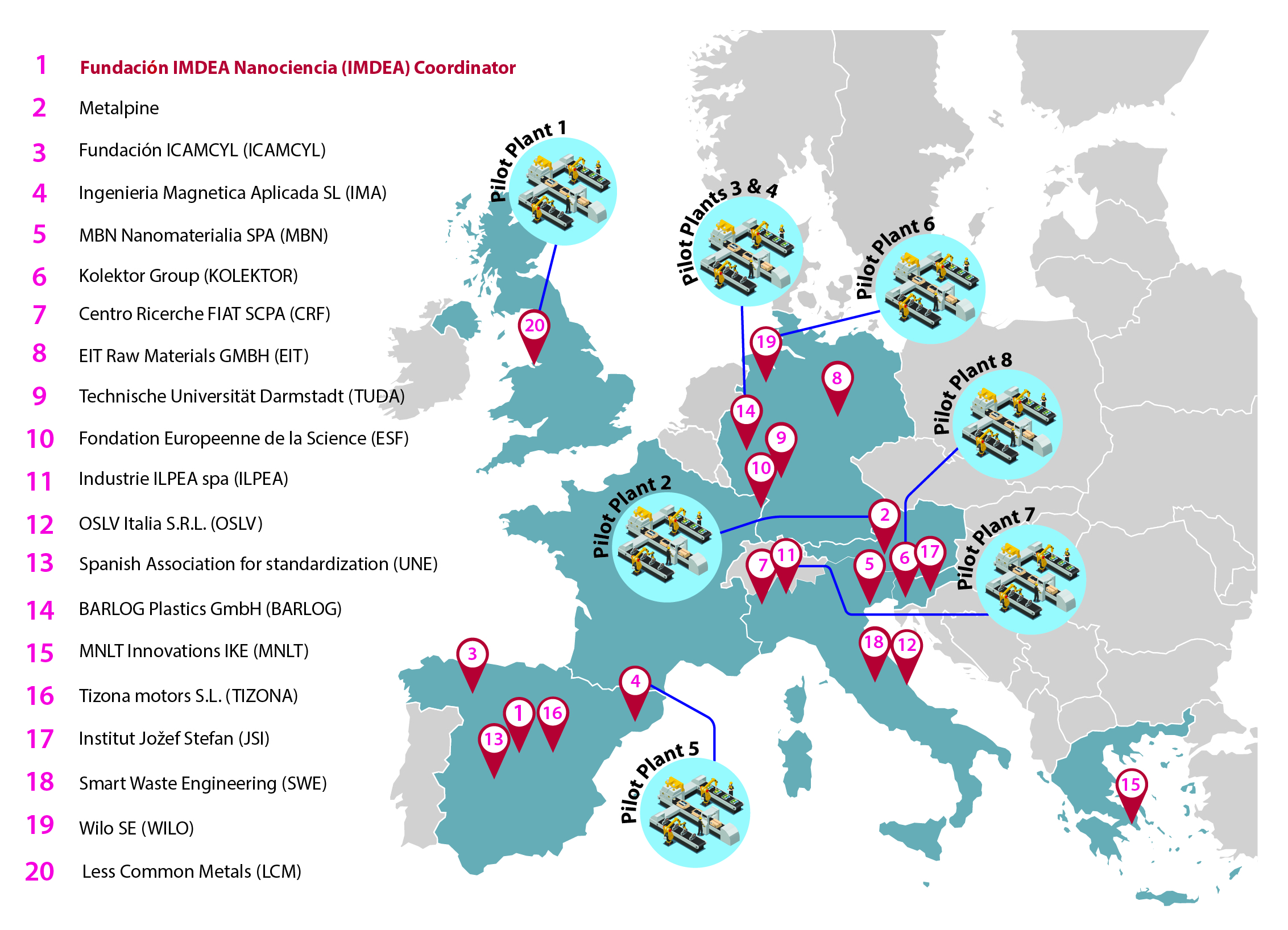

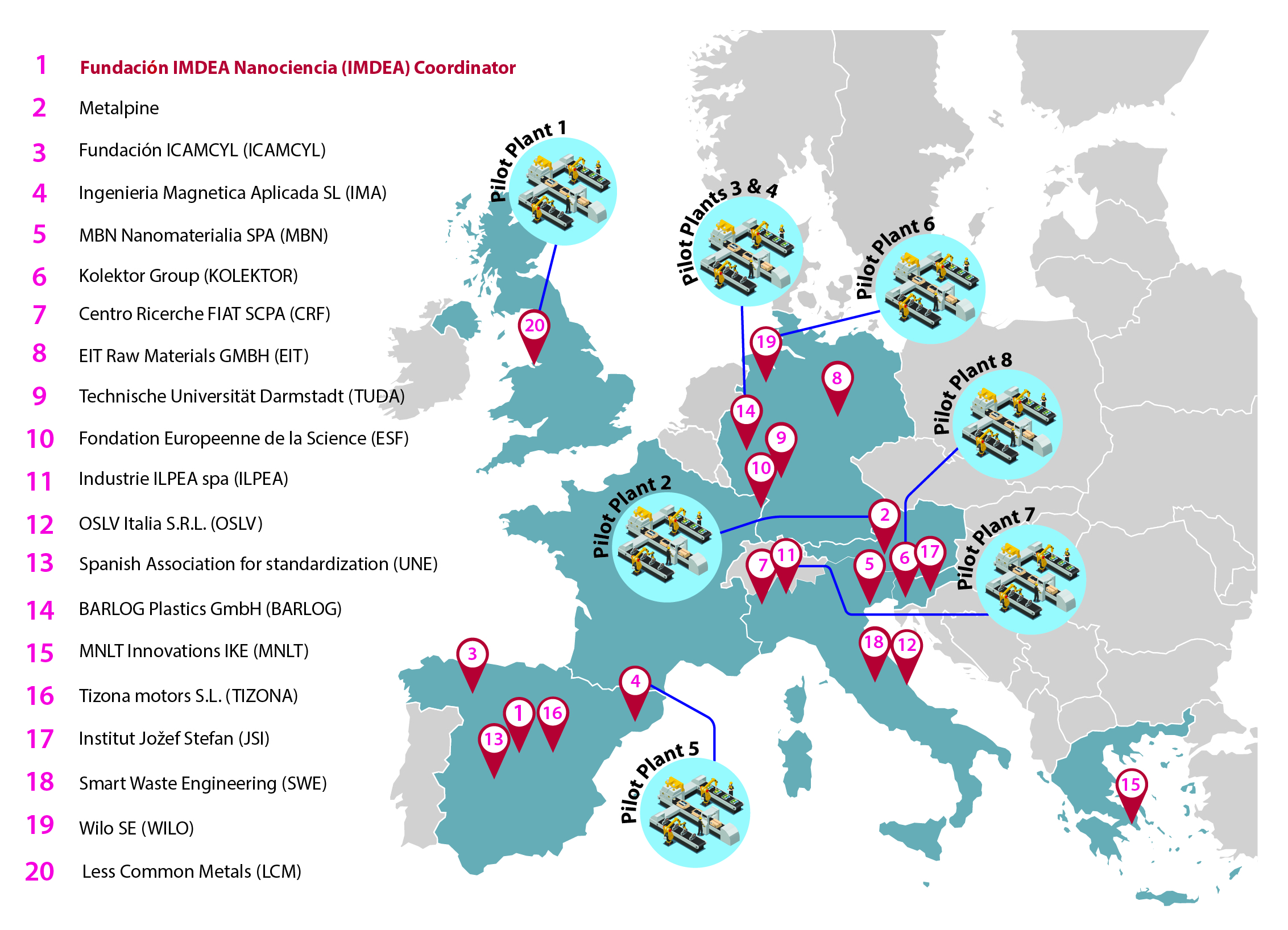

(i) EU H2020 Project “PASSENGER: Pilot Action for Securing a Sustainable European Next Generation of Efficient RE-free magnets” (Ref. 101003914). PASSENGER aims to develop innovative pilot plants in Europe to address an aspect of high economical, technological, social and environmental relevance: a solution for the EU dependency on rare-earth raw materials for permanent magnets, avoiding bottlenecks in the material supply-chain and diminishing the environmental impact. The PASSENGER consortium comprises 20 partners (14 companies) from 8 European countries. The project counts on a €11.3 M budget (€8.9 M from the European Union).

(ii)EU M-era.Net Project “NEXMAG” (Ref. PCIN-2015-126). This project has been designated Success Case by the M.ERA-NET network.

(iii) Bilateral project “ENMA” (Ref. MAT2014-56955-R) between the Northeastern University Boston (Prof. Laura H. Lewis’ Group) and IMDEA Nanociencia, which also involves the company IMA S.L. (Barcelona).

(iv) “3D-MAGNETOH” (Ref. MAT2017-89960-R) involving participation of IMA (Barcelona) and the Institute of Physics - Slovak Academy of Sciences (Slovakia).

(v) Supporting action “EUIN2017-88502”.Industrial collaborations:

(a) Industrial projects "ECNanoManga" and "GAMMA" with the Swedish company Höganäs, world-leading manufacturer of metal powders.

(b) Innovation Fund (“Cheque Innovación”) by Regional Government of Madrid with the company RAMEM S.A. (Madrid).

(c) Industrial collaboration “Bonded Magnets” with IMA S.L.U. (Barcelona).The Group is additionally participating in the project UWIPOM2 [Ref. 857654]; and in the project NanomagCOST (coordinated by Prof. Rodolfo Miranda, Universidad Autónoma de Madrid) [Ref. S2018/NMT-4321].

In the past, the Group has coordinated the EU Project FP7 NANOPYME (Ref. 310516) and a bilateral German-Spanish action exploring the use of rare-earth/metal multilayers in new sensing devices; and has participated in the project NanoFrontMag-CM (coordinated by Prof. Rodolfo Miranda, Universidad Autónoma de Madrid) [Ref. S2013/MIT-2850].

-

Scope

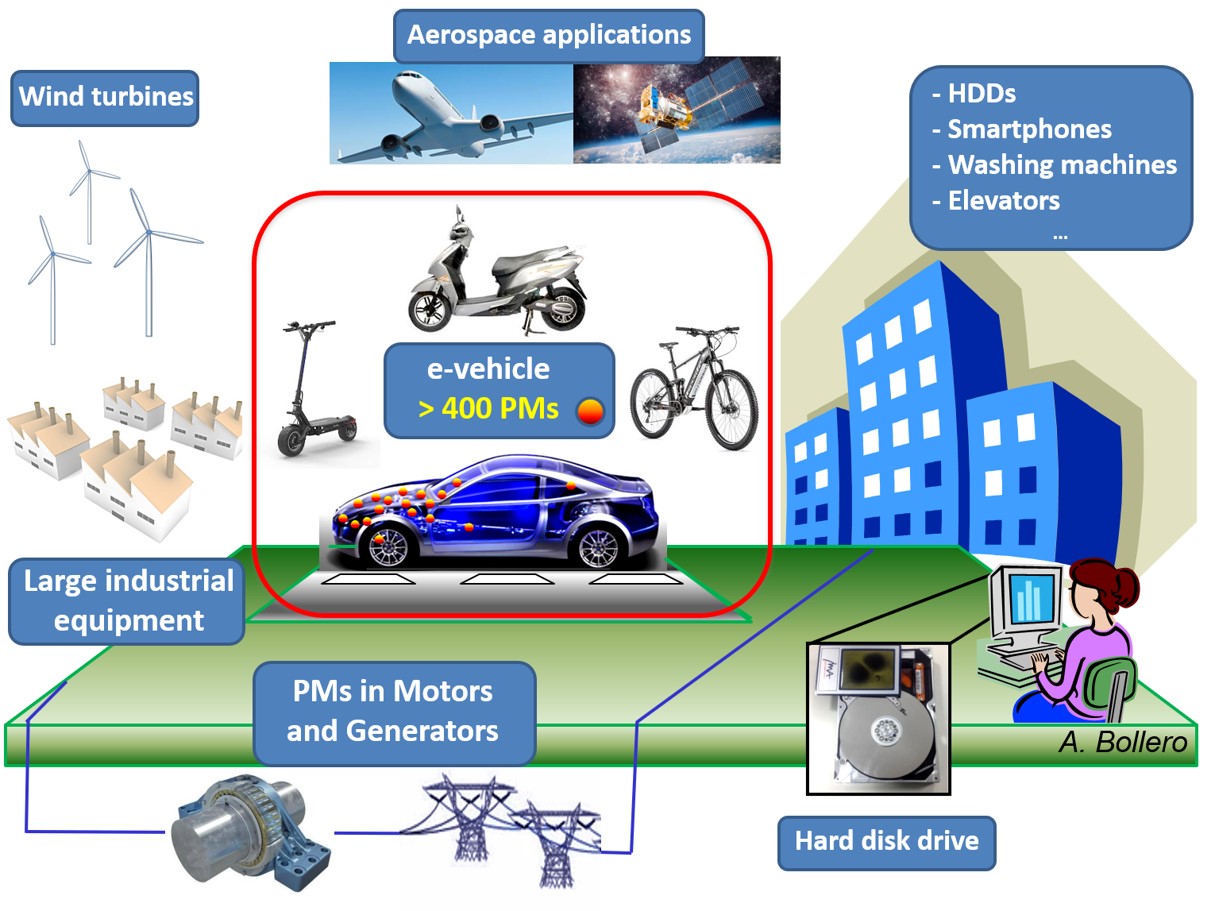

Magnetic materials are important in the production, transmission and use of electrical energy. It has become obvious over the years that an increased use of low carbon technologies is necessary to ensure a high living standard. Permanent magnets (PMs), used in multitude of technological applications, play a very important role in these efforts. Many nowadays applications traditionally use rare earth (RE)-based PMs, as no relevant problems in terms of availability or high and unstable pricing raised at the time of their implementation. The situation has dramatically changed in recent years due to an increased monopoly.

This increased need of PMs in combination with the strategically geographical situation of REs make mandatory, first, an efficient and well focused use of these elements for specific purposes (high performing applications or micro-scalable devices) and, additionally, a reinforcement in the search of PMs alternatives in applications areas where the use of REs may be reduced or totally avoided.

We work actively in collaboration with international research centers and companies in the search of improved and novel permanent magnet materials. Our research is based on three main pillars:

- Development of basic research and its translation to industry and end-users.

- Up-scalability of the procedures to avoid that achieved advances stop at the laboratory.

- Sustainability through recycling and efficient use of the resources.

Figure 1. Permanent magnets (PMs) in nowadays-technological applications: from energy generation, going through energy transformation and to devices. [Image: IMDEA Nanoscience]

RE-free PMs, constituted by non-critical elements would contribute to solve the EU dependency of REs and would revert the situation of the PMs from the nowadays situation which is determined by the geographical distribution of the raw materials to a new market where the know-how and technological development will determine the market leader.

The Group of Permanent Magnets and Applications works in close cooperation with recognized international research centres [Northeastern University Boston (USA), IFE (Norway), IPSAS (Slovakia)…] and well-established companies [Höganäs AB (Sweden), IMA S.L. (Spain)…] in the search of alternatives to RE-PMs and of more efficient and environmentally friendly synthesis and processing routes for PMs.

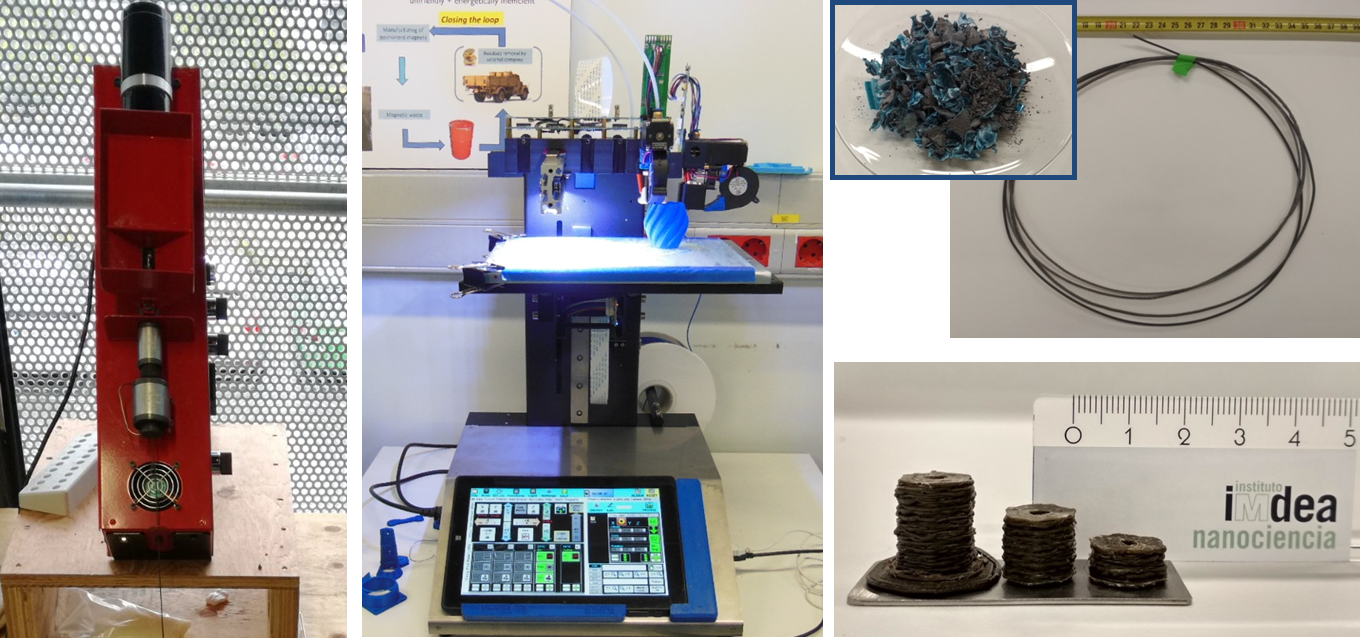

Advanced 3D-printing technology is used by the Group for printing rare earth-free and hybrid Neo/ferrite PMs. Laser-assisted additive manufacturing, typically used for 3D-printing of metallic alloys, is not a feasible option for PMs due to the high temperatures achieved during processing. Thermally controlled 3D-printing makes use of PM/polymer composite filament to print magnetic elements. This approach intends to change the actual technological paradigm based on design of devices according to magnets with predefined geometries (in-catalogue), which lately limits their efficiency.

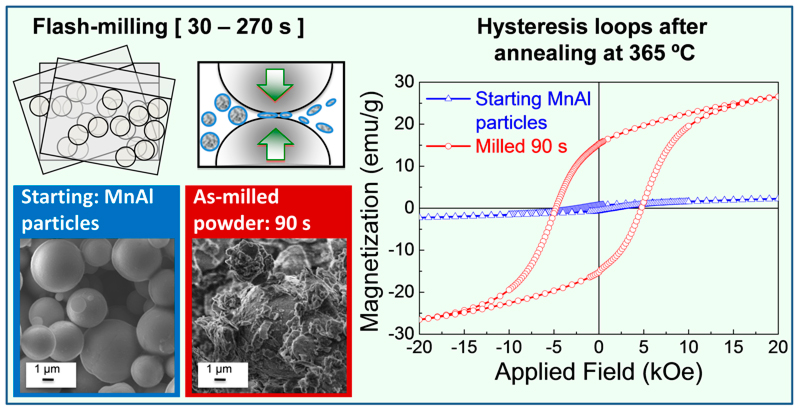

Figure 2. Coercivity development in nanocrystalline MnAl particles achieved by the innovative rapid-milling procedure (30-270 s) followed by reduced-temperature annealing (365ºC/10min). Published in J. Phys. D: Appl. Phys. 50, 105004 (2017).

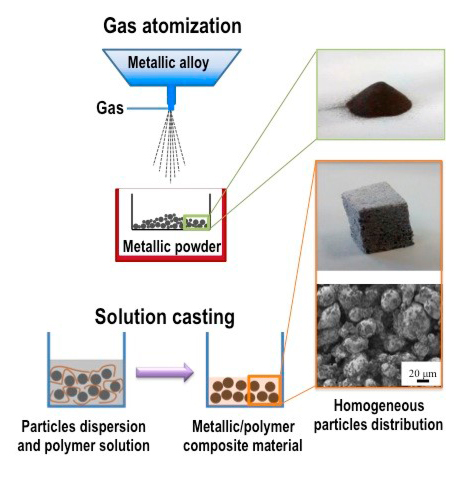

Figure 3. Synthesis of metallic alloys by gas-atomization and preparation of the metallic/polymer composite by the solution casting method.

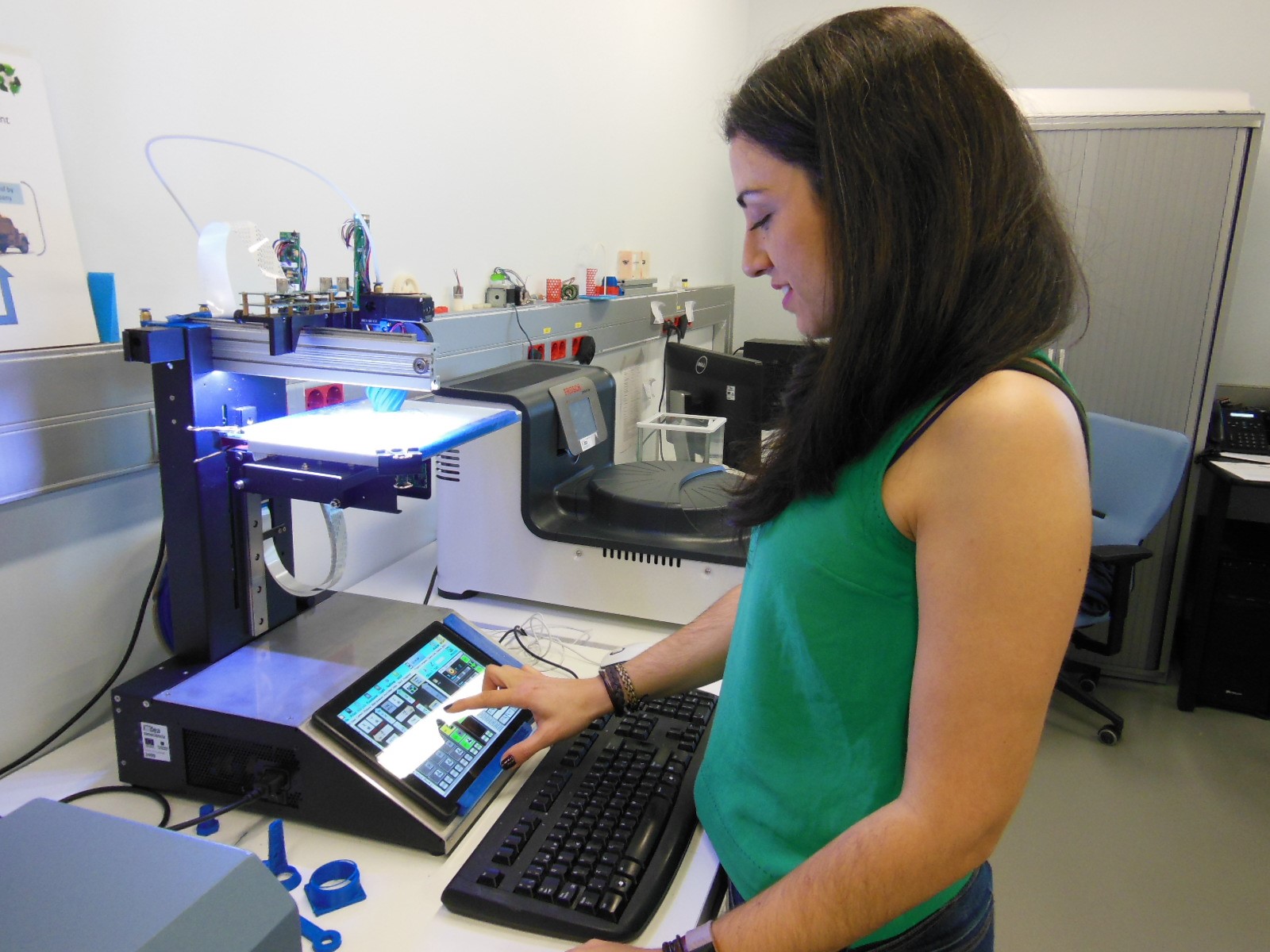

Figure 4. 3D-printer used for high-density materials (PMs and metallic alloys). Photograph of metallic/polymer composite (filling factor: 80 wt%) and filament. 3D printed elements (hexagonal columns) prepared from the filament.

Figure 5. First-time fabrication of permanent magnet filament of MnAlC (extensible to different alloys) and 3D-printed magnetic piece with complex structure. More information at Sci. Technol. Adv. Mater., 19 (1), 465-473 (2018).

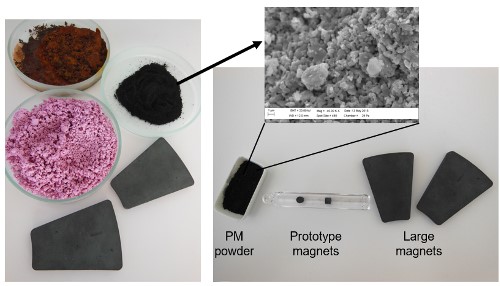

Figure 6. Precursor materials for the synthesis of ferrites and fabricated magnets (prototypes and large) from ferrite powder with permanent magnet properties.

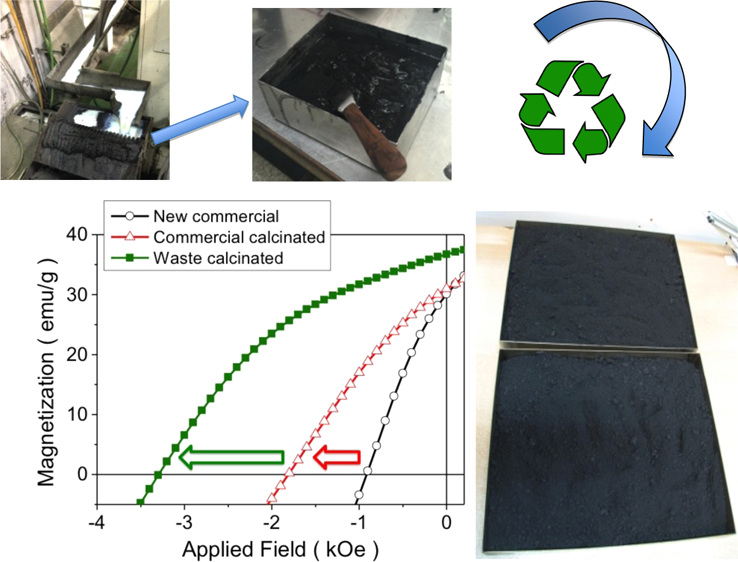

Figure 7. Recycling of ferrite residues in a manufactory plant. The quality of the recycled ferrite powder has been tested and compared to that of the new starting ferrite material. The magnetic properties of the recycled powder not only match those of the starting material acquired by the company for the production of magnets but exceed them. A coercivity value 3.5 times larger than that of the new starting ferrite powder, accompanied by a 25% increase in remanence, makes this material a new and improved ferrite product to re-enter the production chain in the factory with an extended applications range. Extended information: ACS Sustainable Chem. Eng. 5, 3243 (2017)

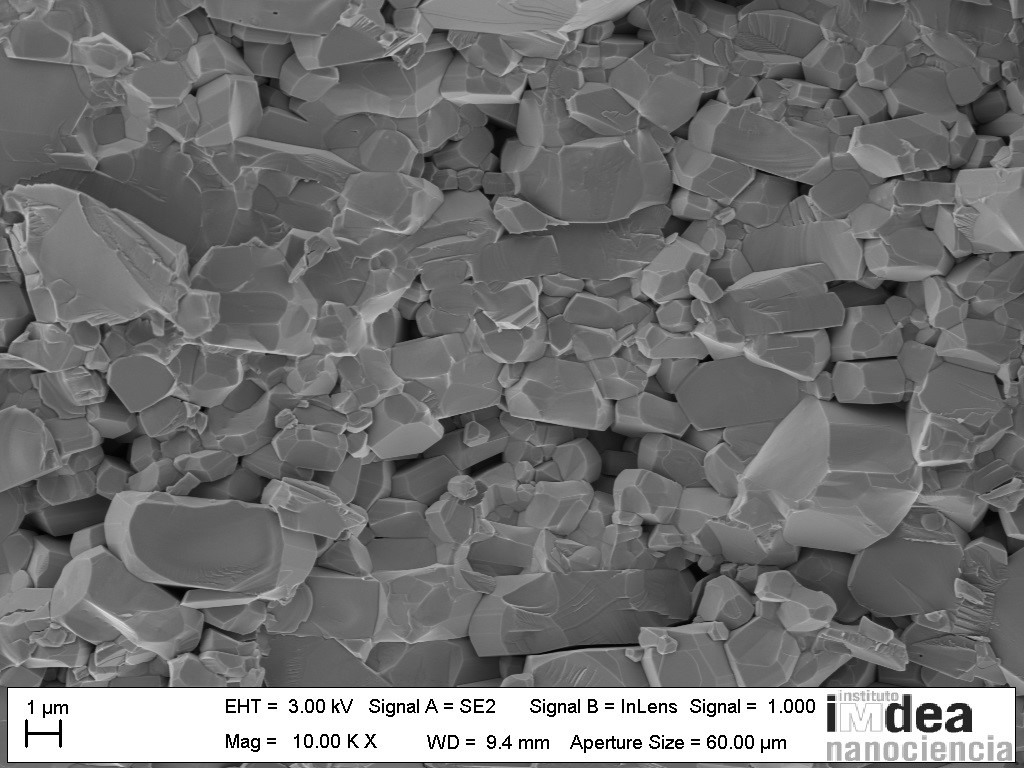

Figure 8. SEM image of Sr-ferrite sintered magnet prepared at IMA S.L. [Image: IMDEA Nanoscience]

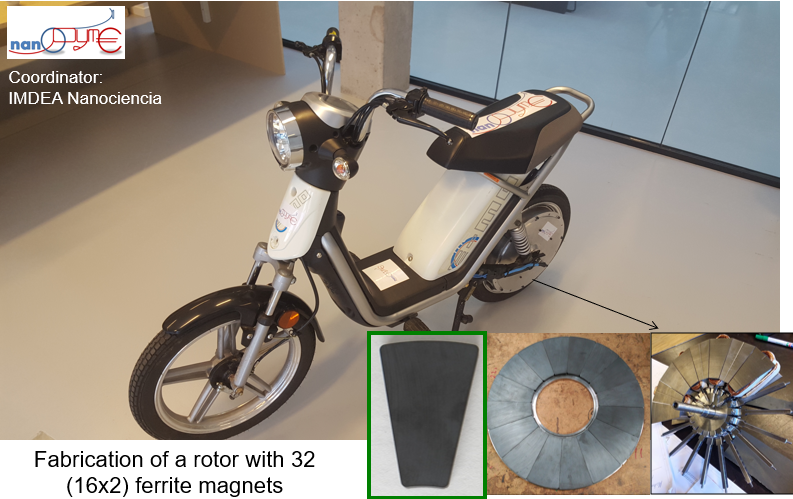

Figure 9. Scooter with an electric ferrite-based motor designed and constructed in the frame of EU- FP7 NANOPYME.

-

Facilities

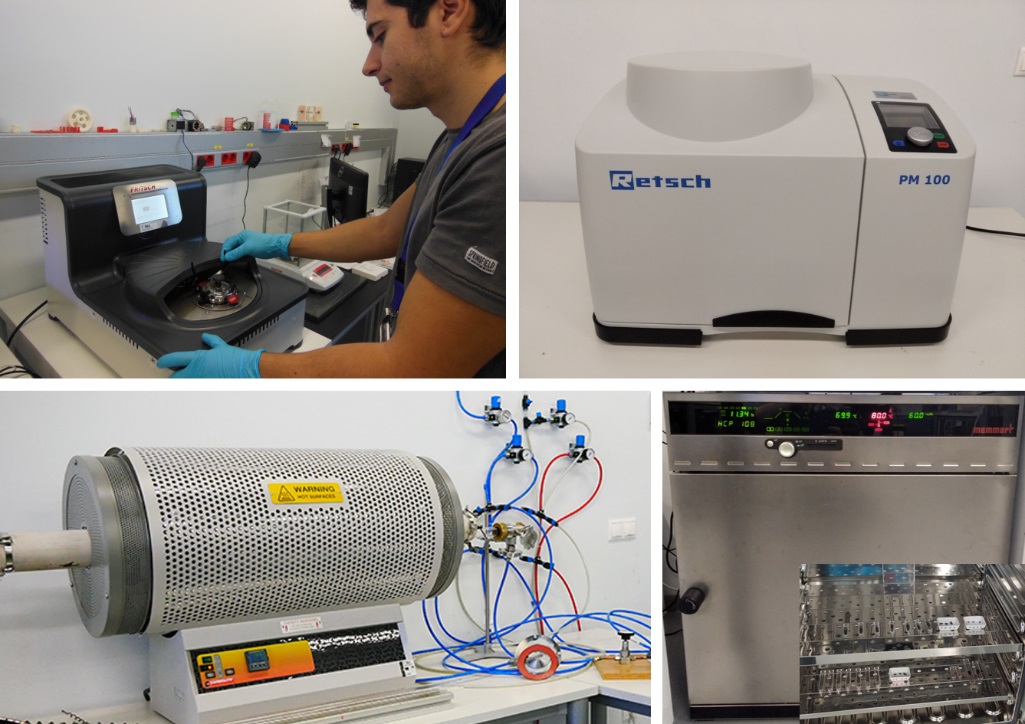

The laboratories dedicated to permanent magnets are divided into six categories:

- Synthesis and processing of magnetic powders and bulk magnets.

High-energy ball milling devices; furnace with operation under controlled atmosphere; humidity chamber for testing under extreme operation conditions (controlled temperature and humidity).

- 3D-Printing.

Equipment for composite (permanent magnet/polymer and metal/polymer) synthesis. Extruder of filament and advanced 3D-printing equipment for fabrication of polymeric and high-density magnetic and/or metallic composite components.

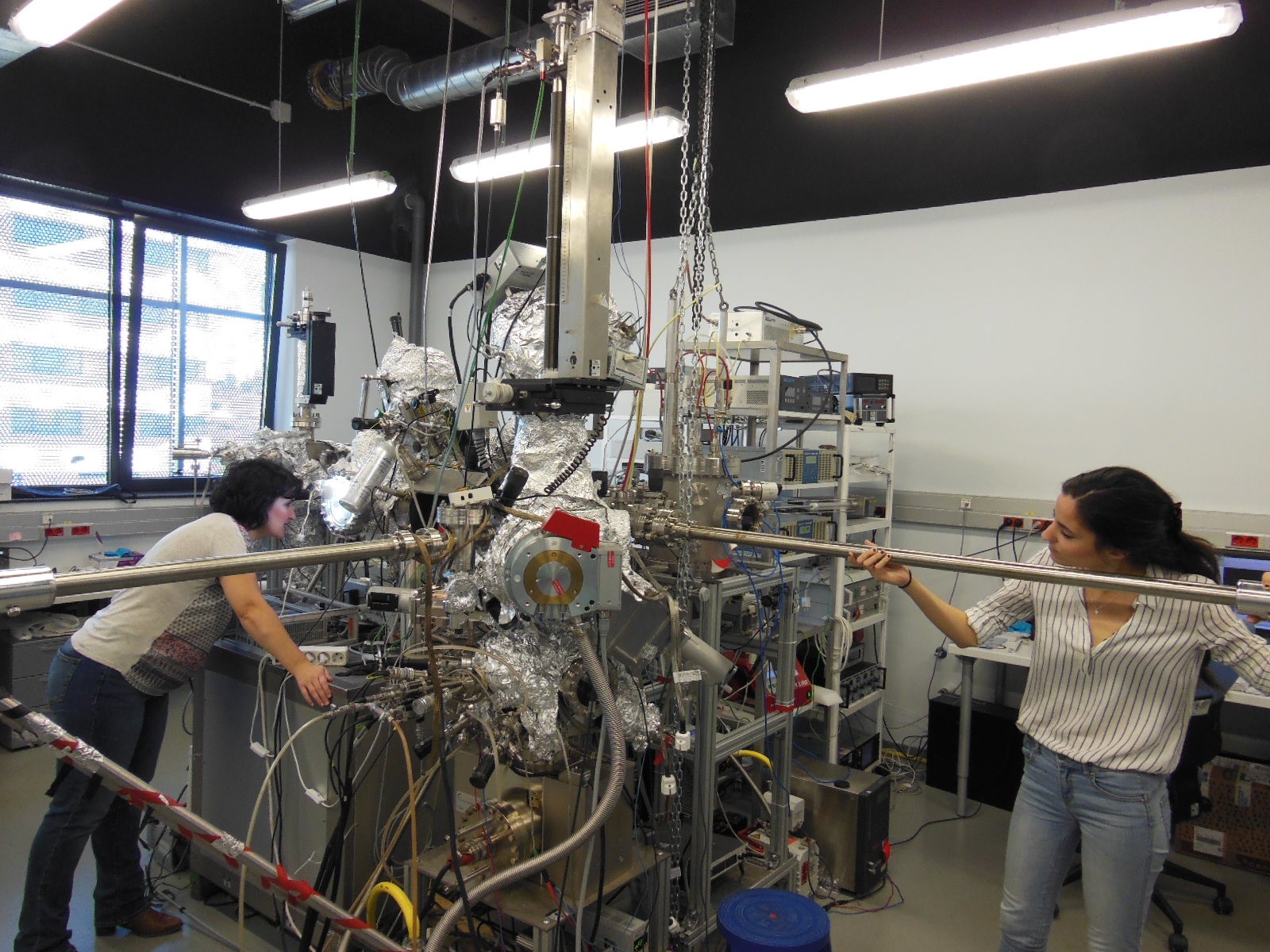

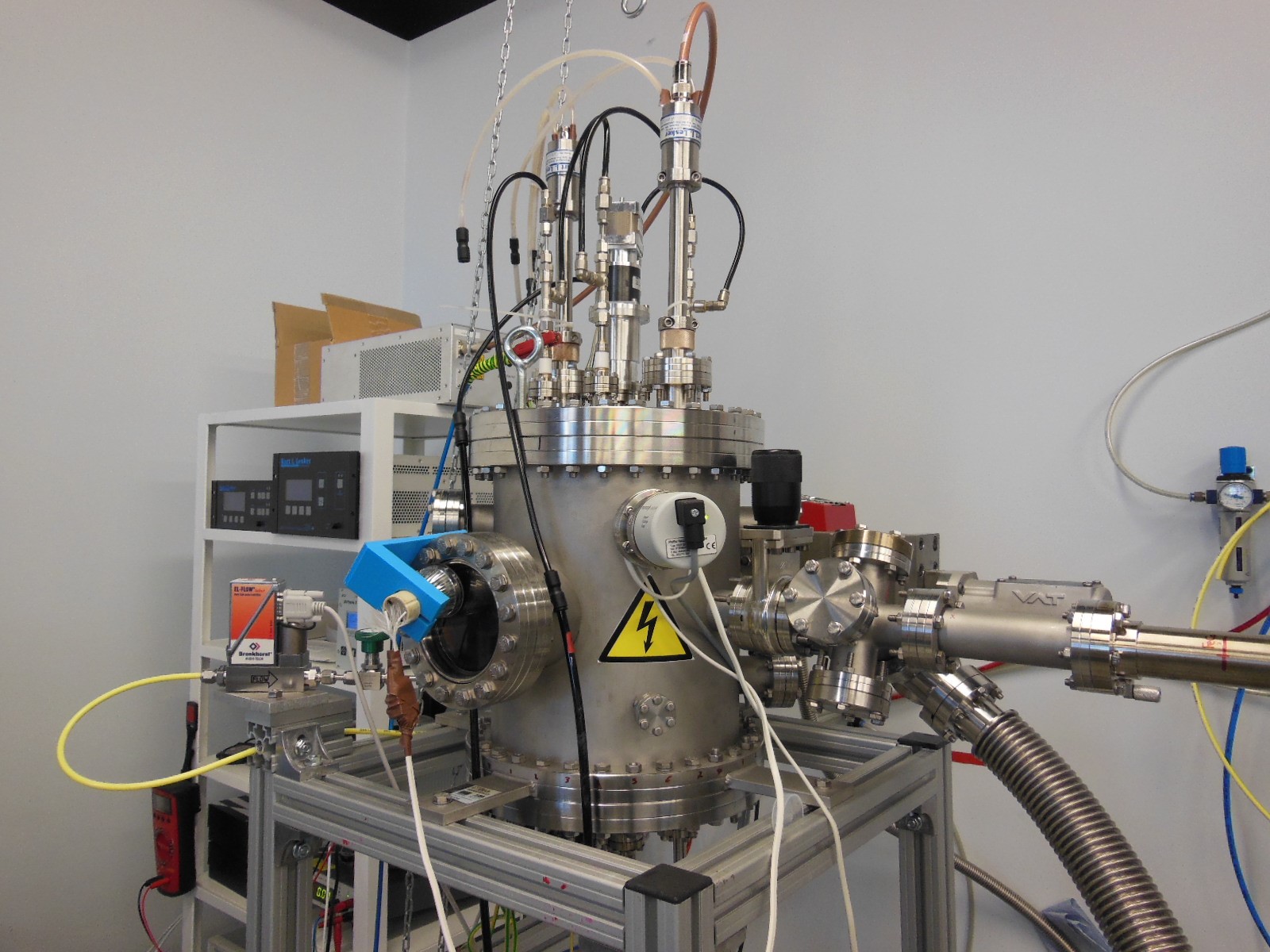

- Thin films growth capabilities.

Molecular beam epitaxy (MBE) equipped with a full range of in-situ characterization techniques (XPS, UPS and LEED); two sputtering devices.

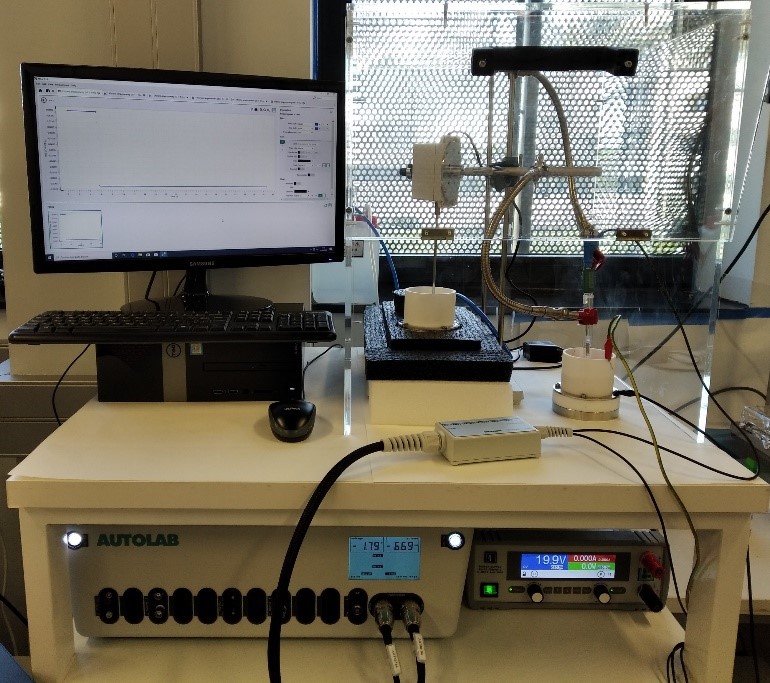

- Electrochemistry experiments.

Equipment for the electrochemical synthesis of complex nanostructures (continuous, multi-layered and core-shell nanowires) with permanent magnet properties; electroplating of metallic elements and alloys; and determination of corrosion resistance by electrochemical corrosion tests.

- Magnetic, morphological, microstructural and compositional characterization.

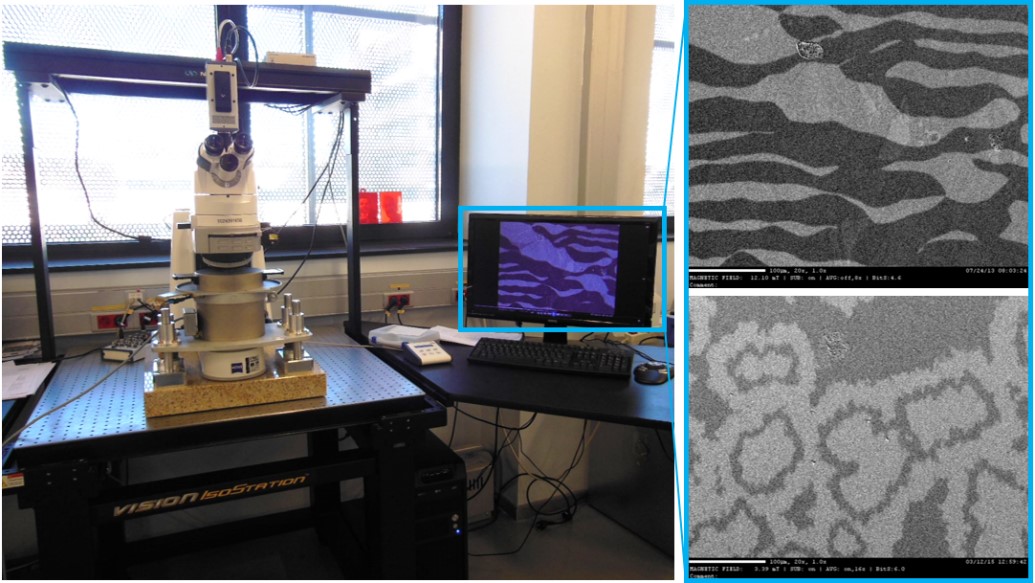

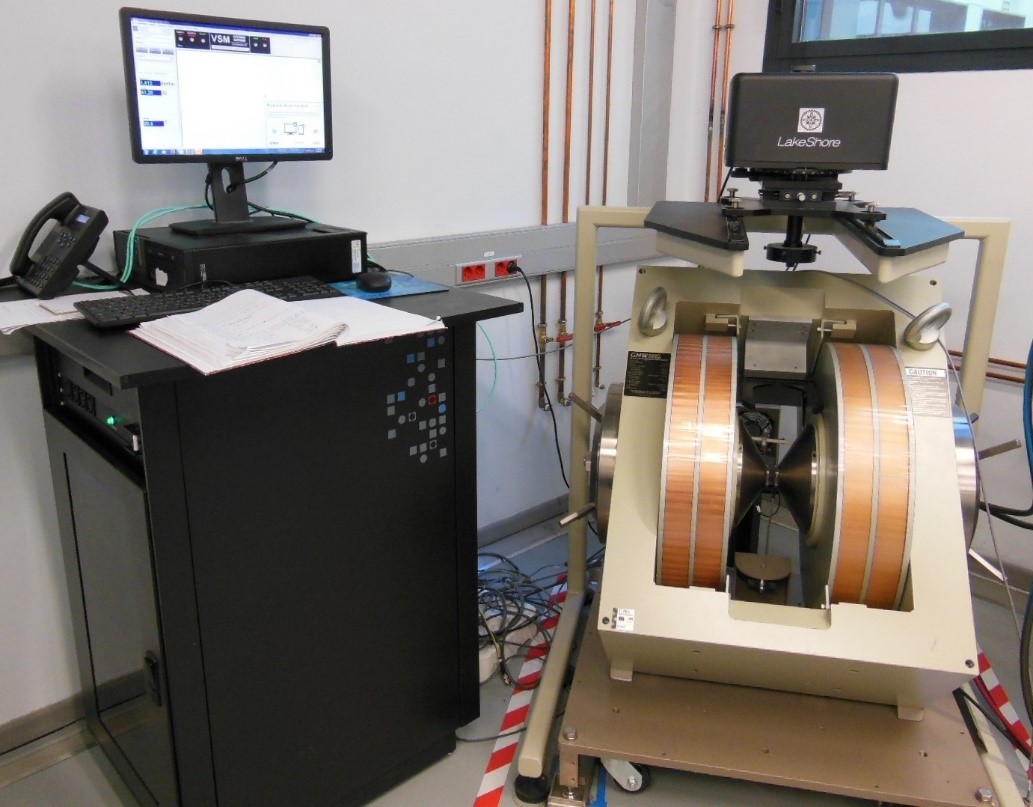

Vectorial vibrating sample magnetometer (v-VSM) with possibility of applying a maximum magnetic field of 3T; three vectorial-magneto-optical Kerr effect (v-MOKE) setups allowing for simultaneous recording of angular hysteresis loops and magnetoresistance curves and operating at low and high temperatures; a high resolution MOKE microscope with possibility of in-situ application of perpendicular and in-plane external magnetic field; teslameter provided with a Hall sensor probe.

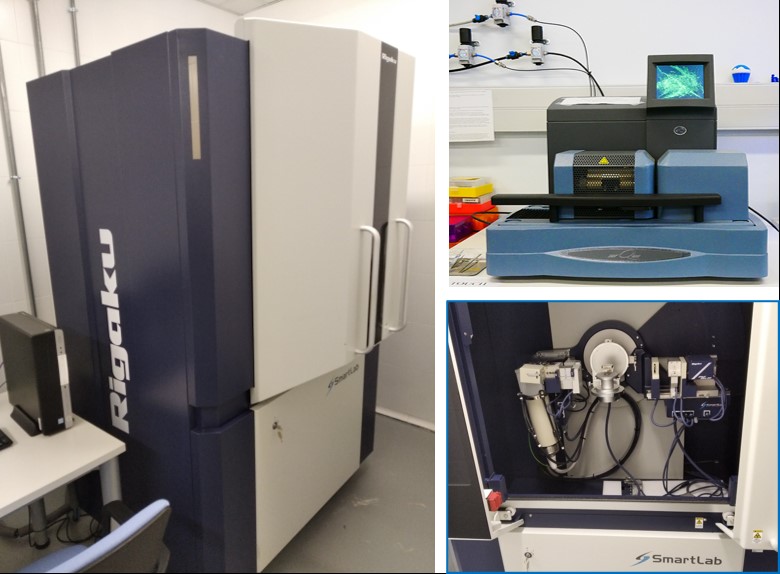

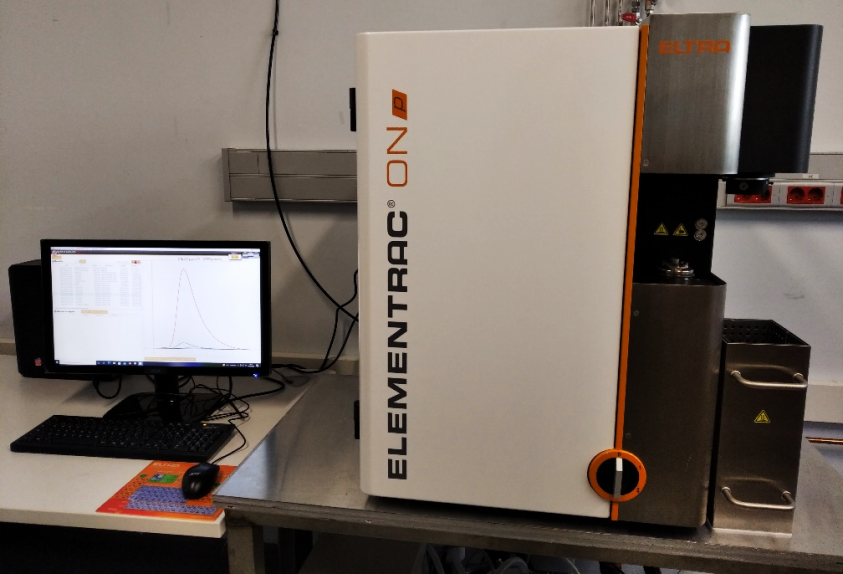

Furthermore, microstructural characterization tools (dual FIB/SEM, SEM equipped with EDX detector, TEM,…), differential scanning calorimeter (DSC), X-ray diffractometer (XRD) and Oxygen/Nitrogen analyzer are also available.

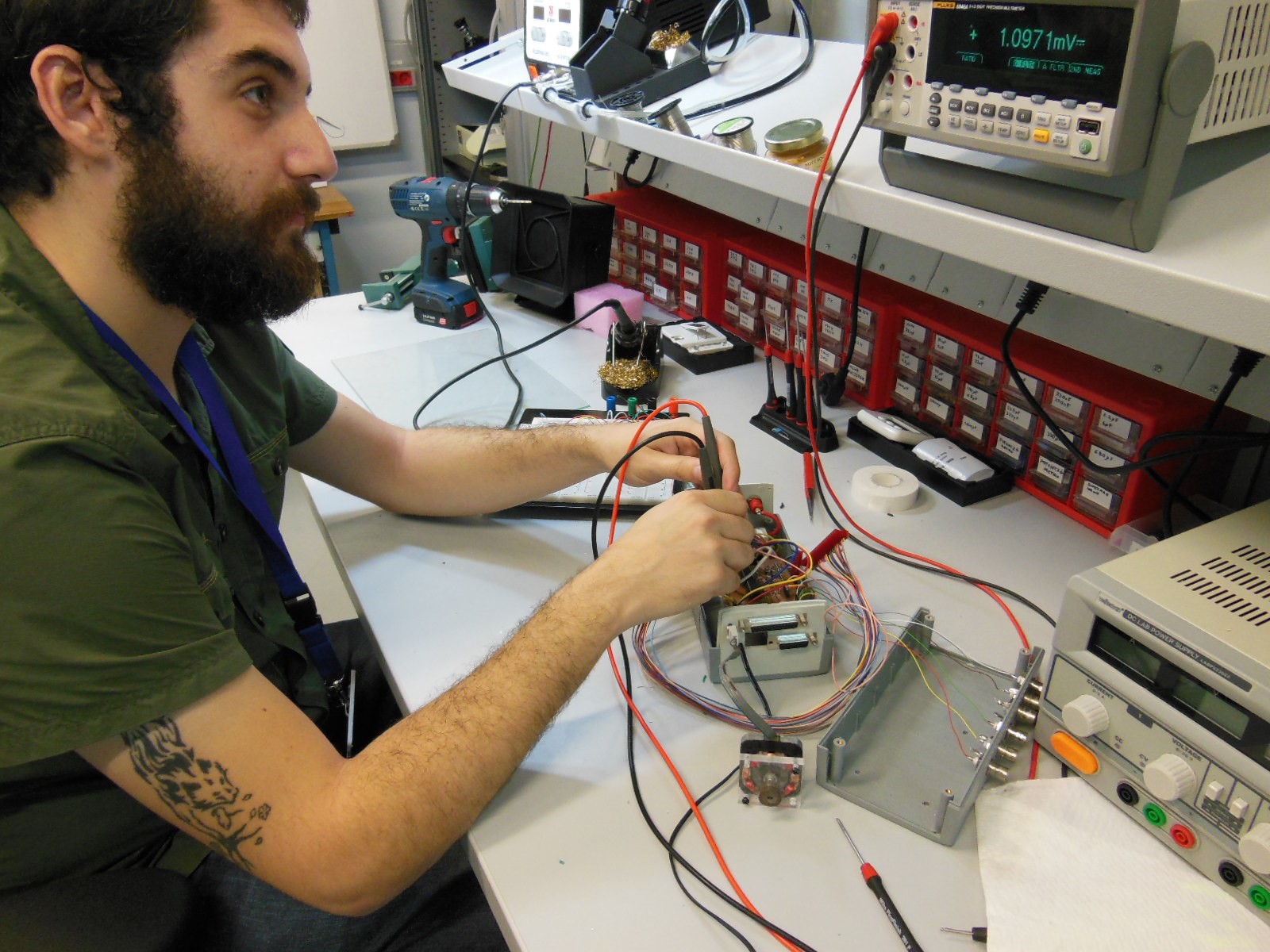

- Electronic capabilities for design and construction of prototypes (motors, sensors…).

-

Projects

The quality of the research carried out by the team is proven by 15 initiatives (national and international ones) coordinated or with a P.I. role by the team during the last 5 years.

The Projects coordinated by the Group are classified in two categories: scientific-technological projects and industrial projects.

ON-GOING PROJECTS

INDUSTRIAL PROJECTS

Project with BOSCH (Germany)

Title: Development of novel high-performance rare earth-free permanent magnets

Financial Entity: BOSCH (Germany)

Duration: 22/08/2022 - 21/08/2025SCIENTIFIC-TECHNOLOGICAL PROJECTS

1. Title: PASSENGER "Pilot Action for Securing a Sustainable European Next Generation of Efficient RE-free magnets" (Ref. 101003914)

Financial Entities: EU Horizon 2020

Duration: 01/05/2021 – 30/04/2025

Project costs: € 11.3 M (€ 8.9 M from the European Union)

2. Title: PLOOTO “Product Passport through Twinning of Circular Value Chains” (Ref. 101092008)

Coordinator: Mr. Kostas Kalaboukas (MAGGLIOLI SPA, Italy).

Financial Entities: EU HORIZON RIA

Duration: 01/01/2023 - 31/12/2025

Project costs: € 8 M3. Title: UWIPOM2 “Ultra-Efficient Wireless POwered Micro-robotic joint” (Ref. 857654)

Coordinator: Dr. Efrén Díez (UAH).

Financial Entities: H2020 FET-Openl

Duration: 01/10/2019 – 30/06/2023

Project costs: € 2.987.000

4. Title: COSMAG “From the Cosmos to the Lab: Development of the L10-FeNi Phase as a Disruptive Permanent Magnet Alternative” (PCI2020-112143)

Consortium: IMDEA Nanociencia (coordinator), IFW-Dresden (Germany), IPSAS (Slovakia), IMA S.L.U. (Spain)

Financial Entities: M-ERA.NET Call with funding through AEI (Spain), SMWK (Germany), SAS (Slovakia)

Duration: 01/10/2020 – 31/03/2023

Funding: € 623.000

5. Title: RETAIN "Recycling through an affordable implementation of nanoscience: sustainable production of permanent magnets in Europe" (Ref. TED2021-132490BI00)

PIs: Dr. Ester M. Palmero

Financial Entities: MICINN

Duration: 01/12/2022 - 30/11/2024

Funding: € 253.0006. Title: NEXUS “Next generation of sustainable permanent magnets with L10 structure” (Ref. PID2020-115215RB-C21)

Coordinators and PIs: Dr. Ester M. Palmero

Coordinated project together with the Group led by Prof. J.J. Suñol's Group at the University of Girona.

Financial Entities: MICINN

Duration: 01/09/2021 - 31/08/2024

Funding: € 121.000

7. MINETHIC "Impulso de la recuperación y valorización de recursos minerales estratégicos para la transición ecológica"

Role in the project: Participating center in R&D activities

Financial Entities: CDTI, MICINN

Duration: 01/01/2023 - 30/06/2025

5. Title: NanoMagCOST “Solutions of Nanomagnetism for Societal Challengues” (Ref. S2018/NMT-4321)

Coordinator: Prof. Rodolfo Miranda (Universidad Autónoma de Madrid)

Duration: 01/01/2019 - 30/04/2023

Funding: € 1.064.800

EDUCATIONAL PROJECT

Title: ExpSkills-REM “Expanding Knowledge and Skills in Rare Earth Permanent Magnets Chain” (Ref. 21104)

Coordinator: Dr. Pavel Korzhavy and Dr. Inna Soroka (KTH, Sweden)

Financial Entities: EIT Raw Materials

Duration: 01/07/2022 - 30/06/2025

Project costs: € 820.000 (€ 734.000 from EIT Raw Materials)

ENDED PROJECTS

INDUSTRIAL PROJECTS

1. Industrial collaboration with Höganäs AB (Sweden)

Title: ECNanoManga

Financial Entity: Höganäs AB (Sweden)

Duration: 01/11/2018 – 30/10/20212. Industrial collaboration with Höganäs AB (Sweden)

Title: GAMMA

Financial Entity: Höganäs AB (Sweden)

Duration: 01/04/2017 - 30/09/2018

3. Innovation Fund "Cheque Innovación" with RAMEM S.A. (Madrid)

Title: "Síntesis e impresión 3D de materiales compuestos de partículas metálicas y polímeros funcionales"

P.I.: Dr. Ester M. Palmero

Financial Entity: Regional Government (Comunidad de Madrid)

Duration: 01/01/2018 - 30/06/20184. Industrial collaboration with IMA S.L. (Barcelona)

Title: "Bonded Magnets"

Financial Entity: IMA S.L. (Barcelona)

Duration: 01/06/2018 - 31/05/2021SCIENTIFIC-TECHNOLOGICAL PROJECTS

1. Title: 3D-MAGNETOH “3D-Printing of Mn-based Magnets for a New Energy and Transport Horizon” (MAT2017-89960-R)

P.I.s: Dr. Ester M. Palmero

Financial Entities: MINECO

Duration: 01/01/2018 – 31/12/2020

Funding: € 90.750

2. Title: NEXMAG “New exchange-coupled Manganese-based magnetic materials” (PCIN-2015-126)

Financial Entities: MINECO - EU M.ERA-NET Call

Duration: 01/12/2015 – 30/11/2018

Project costs: € 739.400. Funding: € 170.000

NEXMAG designated “Success Case” by the M.ERA-NET Network.3. Title: NANOPERMAG “Nanociencia aplicada al desarrollo de imanes permanentes libres de tierras raras mediante tecnologías sostenibles” (Ref. EIN2019-103506)

Financial Entities: MINECO

Duration: 01/01/2019 – 31/12/2020

Funding: € 10.0004. Title: ENMA “Exchange-coupled Nanocomposite Magnets: Towards Rare Earth-Free Permanent Magnets” (MAT2014-56955-R)

Financial Entities: MINECO

Duration: 01/01/2015 – 31/12/2017

Funding: € 60.000

5. Title: “Nueva generación de imanes basados en MnAl mediante impresión 3D para aplicaciones energéticas” (EUIN2017-88502)

Financial Entities: MINECO

Duration: 01/02/17 – 31/12/18

Funding: € 13.5006. Title: NANOFRONTMAG “New Frontiers in Fundamental and Applied Nanomagnetism” (S2013/MIT-2850)

Coordinator: Prof. Rodolfo Miranda (Universidad Autónoma de Madrid)

Financial Entities: Regional Government (Comunidad de Madrid)

Duration: 01/06/2015 – 30/05/2018

Funding: € 894.400

7. NANOPYME “Nanocrystalline Permanent Magnets Based on Hybrid Metal-Ferrites” [Ref. 310516].

Financial Entity: FP7 E.U. [7th Framework Programme]

Duration: 01/12/2012 – 31/11/2015

Project costs: 4.5 M€. Funding: 3.5 M€

-

Publications

2022

J.M. Díez, J.L. Fernández-Cuñado, P. Lapa, R. Solís, I. Arnay, P. Pedraz, P. Perna, A. Bollero, R. Miranda, I.K. Schuller, and J. Camarero, Interfacial exchange phenomena driven by ferromagnetic domains, Adv. Mater. Interfaces 9 (21), 2200331 (2022).

D. Cabrera, T. Yoshida, T. Rincón-Domínguez, J.L. Fernández-Cuñado, G. Salas, A. Bollero, M.P. Morales, J. Camarero, and F.J. Terán, Superparamagnetic-blocked state transition under alternating magnetic fields: towards determining the magnetic anisotropy in magnetic suspensions, Nanoscale 14, 8789-8796 (2022).

A. Bollero and E.M. Palmero, Recent advances in hard - ferrite magnets, in J.J. Croat and J. Ormerod (eds.) Modern Permanent Magnets, pp. 65-112, Elsevier (2022)

2021

J. Rial, P. Švec, P. Švec Sr., A. Bollero, and S. Deledda, Coercivity development in MnAl ribbons by microstructural modifications achieved through cold-rolling process, J. Magn. Magn. Mater. 529, 167826 (2021).

L. Zha, C. Kim, C. Yun, D. Zhou, W. Li, X. Kong, L. Han, W. Yang, S. Liu, J. Han, C. Wang, H. Du, W. Xia, A. Bollero, and J. Yang, A novel strategy for the fabrication of high-performance nanostructured Ce-Fe-B magnetic materials via electron-beam exposure, Sci. China Mater. 64, 2519-2529 (2021).

M. Villanueva, E.H. Sánchez, P. Olleros-Rodríguez, P. Pedraz, P. Perna, P.S. Normile, J.A. de Toro, J. Camarero, C. Navío, and A. Bollero, Effective control of the magnetic anisotropy in ferromagnetic MnBi micro-islands, J. Alloys Compd. 852, 156731 (2021).

E.M. Palmero and A. Bollero, 3D and 4D printing of functional and smart composite materials, in “Encyclopedia of Materials: Composites” – Materials Science and Materials Engineering, Vol. 2, pp. 402-419, Elsevier (2021)

2020

C. Muñoz-Rodríguez, L. Feng, E.M. Palmero, T. Mix, J. Rial, F. Olsson, B. Skårman, H. Vidarsson, P.-O. Larsson, T.G. Woodcock, and A. Bollero, Fabrication of bulk τ MnAl–C magnets by hot-pressing from ε-phase gas-atomized and milled powder, J. Alloys Compd. 847, 156361 (2020).

E.M. Palmero, D. Casaleiz, J. de Vicente, B. Skårman, H Vidarsson, P.-O. LArsson, and A. Bollero, Effect of particle size distribution on obtaining novel MnAl-based permanent magnet composites and flexible filaments for 3D-printing, Addit. Manuf. 33, 101179 (2020).

I. García-Cortés, S. Cabrera, M. Medrano, A. Moroño, P. Muñoz, A. Soleto, I. Bugallo, A. Nieto, R. Altimira, A. Bollero, J. Camarero, and J.L.F. Cuñado, RMATE: A device to test radiation-induced effects under controlled magnetic field and temperature, Fusion Eng. Des. 154, 111431 (2020).

J. Rial, E.M. Palmero, and A. Bollero, Efficient nanostructuring of isotropic gas-atomized MnAl powder by rapid milling (30 s), Engineering 6 (2), 173-177 (2020).

A. Bollero, V. Neu, V. Baltz, D. Serantes, J.L.F. Cuñado, J. Pedrosa, E.M. Palmero, M. Seifert, B. Dieny, R.P. del Real, M. Vázquez, O. Chubykalo-Fesenko, and J. Camarero, An extraordinary chiral exchange-bias phenomenon: engineering the sign of the bias field in orthogonal bilayers by a magnetically switchable response mechanism, Nanoscale 12, 1155-1163 (2020).

2019

J.L.F. Cuñado, J. Camarero, F.J. Pedrosa, N.M. Nemes, M. Sanz, M. Oujja, E. Rebollar, J.F. Marco, J. de la Figuera, M. Monti, M. Castillejo, T. Feher, B. Nafradi, L. Forró and A. Bollero, Evidence of anomalous switching of the in-plane magnetic easy axis with temperature in Fe3O4 film on SrTiO3:Nb by v-MOKE and ferromagnetic resonance, Nanoscale 11, 19870-19876 (2019).

E.M. Palmero, D. Casaleiz, J. de Vicente, J. Hernández-Vicen, S. López-Vidal, E. Ramiro, and A. Bollero, Composites based on metallic particles and tuned filling factor for 3D-printing by Fused Deposition Modeling, Compos. Part A Appl. Sci. Manuf. 124, 105497 (2019).

M. Villanueva, C. Navío, E. Céspedes, F. Mompeán, M. García-Hernández, J. Camarero, and A. Bollero, MnBi thin films for high temperature permanent magnet applications, AIP Adv. 9, 035325 (2019).

V. Øygarden, J. Rial, A. Bollero, and S. Deledda, Phase-pure τ-MnAlC produced by mechanical alloying and a one-step annealing route, J. Alloys Compd. 779, 776-783 (2019).

E.M. Palmero, D. Casaleiz, N.A. Jiménez, J. Rial, J. de Vicente, A. Nieto, R. Altimira, and A. Bollero, Magnetic-polymer composites for bonding and 3D-printing of permanent magnets, IEEE Trans. Magn. 55 (2), 2101004 (2019).

2018

C. Navío, M. Villanueva, E. Céspedes, F. Mompeán, M. García-Hernández, J. Camarero, and A. Bollero, Ultrathin films of L10-MnAl on GaAs (001): A hard magnetic MnAl layer onto a soft Mn-Ga-As-Al interface, APL Mater. 6, 101109 (2018).

J. Rial, P. Švec, E.M. Palmero, J. Camarero, P. Švec Sr., and A. Bollero, Severe tuning of permanent magnet properties in gas-atomized MnAl powder by controlled nanostructuring and phase transformation, Acta Mater., 157, 42-52 (2018).

E.M. Palmero, J. Rial, J. de Vicente, J. Camarero, B. Skårman, H. Vidarsson, P.-O. Larsson, and A. Bollero, Development of permanent magnet MnAlC/polymer composites and flexible filament for bonding and 3D-printing technologies, Sci. Technol. Adv. Mater., 19 (1), 465-473 (2018).

2017

A.Bollero, J. Rial, M. Villanueva, K.M. Golasinski, A. Seoane, J. Almunia, and R. Altimira, Recycling of strontium ferrite waste in a permanent magnet manufacturing plant, ACS Sustainable Chem. Eng., 5 (4), 3243-3249 (2017).

J.Rial, M. Villanueva, E. Céspedes, N. López, J. Camarero, L.G. Marshall, L.H. Lewis, and A. Bollero, Application of a novel flash-milling procedure for coercivity development in nanocrystalline MnAl permanent magnet powders, J. Phys. D: Appl. Phys., 50 (10), 105004 (2017).

M.N. Guzik, K.M. Golasinski, F.J. Pedrosa, P. Jenuš, A. Bollero, B.C. Hauback, and S. Deledda, Influence of ultra-short cryomilling on the microstructural and magnetic properties of cobalt ferrite, J. Alloys Compd., 721, 440-448 (2017).

E.Céspedes, M. Villanueva, C. Navío, F.J. Mompeán, M. García-Hernández, A. Inchausti, P. Pedraz, M.R. Osorio, J. Camarero, and A. Bollero, High coercive LTP-MnBi for high temperature applications: From isolated particles to film-like structures, J. Alloys Compd., 729, 1156-1164 (2017).

J.Y. Law, J. Rial, M. Villanueva, N. López, J. Camarero, L.G. Marshall, J.S. Blázquez, J.M. Borrego, V. Franco, A. Conde, L.H. Lewis, and A. Bollero, Study of phases evolution in high-coercive MnAl powders obtained through short milling time of gas-atomized particles, J. Alloys Compd., 712, 373-378 (2017).

J.L.F. Cuñado, A. Bollero, T. Pérez-Castañeda, P. Perna, F. Ajejas, F.J. Pedrosa, A. Gudín, A. Maldonado, M.A. Niño, R. Guerrero, D. Cabrera, F.J. Terán, R. Miranda, and J. Camarero, Emergence of the Stoner-Wohlfarth astroid in thin films at dynamic regime, Sci. Rep., 7, 13474 (2017).

E.Céspedes, G. Rodríguez-Rodríguez, C. Navío, M.R. Osorio, R. Guerrero, F.J. Pedrosa, F.J. Mompeán, M. García-Hernández, J.F. Fernández, A. Quesada, J. Camarero, and A. Bollero, Inter-grain effects on the magnetism of M-type strontium ferrite, J. Alloys Compd., 692, 280-287 (2017).

2016

F.J. Pedrosa, J. Rial, K.M. Golasinski, M.N. Guzik, A. Quesada, J.F. Fernández, S. Deledda, J. Camarero, and A. Bollero, Towards high performance CoFe2O4 isotropic nanocrystalline powder for permanent magnet applications, Appl. Phys. Lett., 109, 223105 (2016).

N.Jackson, F.J. Pedrosa, A. Bollero, A. Mathewson, and O.Z. Olszewski, Integration of thick-film permanent magnets for MEMS applications, J. Microelectromech. Syst., 25 (4), 716-724 (2016).

J.M. Colino, M.A. Arranz, A.J. Barbero, A. Bollero, and J. Camarero, Surface magnetization and the role of pattern defects in various types of ripple patterned films, J. Phys. D: Appl. Phys., 49 (13), 135002 (2016).

F.J. Pedrosa, J. Rial, K.M. Golasinski, M. Rodríguez-Osorio, G. Salas, D. Granados, J. Camarero, and A. Bollero, Tunable nanocrystalline CoFe2O4 isotropic powders obtained by co-precipitation and ultrafast ball milling for permanent magnet applications, RSC Adv., 6, 87282-87287 (2016).

A.Quesada, C. Granados-Miralles, A. López-Ortega, S. Erokhin, E. Lottini, F.J. Pedrosa, A. Bollero, A.M. Aragón, F. Rubio-Marcos, M. Stingaciu, G. Bertoni, C. de Julián Fernández, C. Sangregorio, J.F. Fernández, D. Berkov, and M. Christensen, Energy product enhancement in imperfectly exchange-coupled nanocomposite magnets, Adv. Electron. Mater., 2 (4), 1500365 (2016).

2015

P.Perna, F. Ajejas, D. Maccariello, J.L. Fernández-Cuñado, R. Guerrero, M.A. Niño, A. Bollero, R. Miranda, and J. Camarero, Interfacial exchange-coupling induced chiral symmetry breaking of spin-orbit effects, Phys. Rev. B, 92, 220422 (2015).

F.J. Pedrosa, J. Rial, K.M. Golasinski, J. Camarero, and A. Bollero, CoFe2O4 isotropic powders for permanent magnet applications, IEEE EUROCON 2015.

J.L. Cuñado, F.J. Pedrosa, F. Ajejas, A. Bollero, P. Perna, F.J. Terán, R. Miranda, and J. Camarero, Note: Vectorial-magneto optical Kerr effect technique combined with variable temperature and full angular range all in a single setup, Rev. Sci. Instrum., 86 (4), 046109 (2015).

A.Bollero, F.J. Pedrosa, J.L. Cuñado, J. Camarero, M. Seifert, V. Neu, V. Baltz, D. Serantes, O. Chubykalo-Fesenko, R.P. del Real, M. Vázquez, L. Schultz, B. Dieny, and R. Miranda, Extraordinary exchange-bias effects in coupled SmCo5 (perpendicular)/CoFeB (in-plane) bilayers, 2015 IEEE Magnetics Conference (INTERMAG).

2014

P.Perna, D. Maccarielo, C. Rodrigo, J.L.F. Cuñado, M. Muñoz, J.L. Prieto, M.A. Niño, A. Bollero, J. Camarero, and R. Miranda, Direct experimental determination of the anisotropic magnetoresistive effects, Appl. Phys. Lett., 104, 202407 (2014).

P.Sirvent, E. Berganza, A.M. Aragón, A. Bollero, A. Moure, M. García-Hernández, P. Marín, J.F. Fernández, and A. Quesada, Effective high-energy ball milling in air of Fe65Co35 alloys, J. Appl. Phys., 115, 17B505 (2014).

E.Jiménez, N. Mikuszeit, J.L. Cuñado, P. Perna, F.J. Pedrosa, D. Maccariello, C. Rodrigo, M.A. Niño, A. Bollero, J. Camarero, and R. Miranda, Vectorial Kerr magnetometer for simultaneous and quantitative measurements of the in-plane magnetization components, Rev. Sci. Instrum., 85 (5), 053904 (2014).